GLOSSARY

BALANCE

The adjustment of paper variables, attributes and materials such as thickness, weight, gloss, pigments and binders to achieve the best possible finished product.

BASE STOCK

Uncoated paper, created in the first step of the papermaking process on which coating is applied.

BINDER

The liquid component of coating that serves to bind the pigment particles together and bind the coating to the base stock.

BLADE COATER

An angled blade in the paper or coating machine that controls the thickness of the applied coating and smooths the surface.

BRIGHTNESS

The amount of light reflected by a paper sample at a specified wavelength. ex (457 nm.)

CELLULOSE

Material that forms the cell walls of trees from which fiber is taken.

CLAYS

Natural, fine-grained, plate-like white pigment used as a coating pigment. A number of grades are available depending on particle size and shape, as well as brightness.

COATING

A combination of binders and pigments applied to paper which defines the color and creates the printing surface. Each coating is formulated to match the finish.

ECF ELEMENTAL CHLORINE FREE

Chlorine compounds replace elemental chlorine in the bleaching process. The result is the same bright white pulp, with no detectable chlorine levels.

BINDING

GOING WITH THE GRAIN

Understanding grain direction is especially useful when designing for folding and binding, and it can work to your advantage. Pages with the grain parallel to the binding lie flat, turn easily and are less likely to develop waves. Paper grain and how it relates to stiffness are important factors to consider. To avoid sagging, the grain direction should be perpendicular to the supporting edge of display cards, file folders and index cards.

Saddle-stitched projects should be designed with page quantities divisible by four, because each sheet, once bound, makes four pages. For work that is to be perfect bound, the number to remember is two, comprising the back and front of the sheet. However, you can count on Typecraft to determine the form that’s most appropriate for your project.

BINDING OPTIONS

Saddle Wire Stitch: For an example of saddle-stitching, pick up just about any magazine or catalog. With this method, pages are spread open at the center, then hung on saddle to be stitched, or stapled, through the fold line at the spine. Ideal for projects with no more than about 60 pages, depending on the sheet weight, this is the simplest and most economical way to bind. Advantages: Allows the book to lie flat for reading ease; can be bound with either a self-cover or separate cover; economical. Disadvantages: page count must be divisible by four, restricting number of pages; least flexible of all binding options.

SIDE-WIRE STITCH

A useful alternative for materials that are too thick to saddle-stitch, this method passes wire from the front page to the back about a ¼” from the interior seam. Advantages: Useful when used to reinforce perfect bound projects; accommodates ultiple sheet weights and sizes; offers single-sheet insertion ofr flexible page count; can enhance aethetics for specialty pieces. Disadvantages: Prevents pages from opening flat.

WIRE-O AND SPIRAL

A method in which pages and cover are held together by a metal coil. Though more expensive than wire-stitching, mechanical bindings allow their contents to open wide and lie perfectly flat. Advantages: Lays flat; pages can be removed without detection; adaptable to different paper types; offers single-sheet insertion for flexible page count; bindings come in a wide variety of colors. Disadvantages: Expense; can detract from project aesthetics.

PERFECT BINDING

Most annual reports and bigger catalogs employ this attractive method, in which pages are assembled in groups, or signatures, and bound together with flexible adhesive, then covered. Advantages: Accommodates greater number of pages and higher page weights than saddle-stitch; accommodates multiple sheet weights and sizes; allows intermix of stocks, provides clean, finished edge. Disadvantages: After pages are collected into signatures, binding edge is ground off to improve adhesion. Does not lay flat; crossover images and type may be lost in the gutter.

CASE OR EDITION

The conventional method used in most hardcover books. Sheets are folded into 16- or 32-page signatures, pasted with end leaves and sewn together. This process culminates in a hardcover, which ensures durability for years to come. Advantages: Provides perfect crossover of images page to page; archival quality. Disadvantages: Most expensive binding method.

SCORING

In general, you will want to channel score if your stock is 100-lb. text or heavier, or if the job’s height/width ratio is greater than 3:1. If your stock is 80-lb. text and folds against the grain, ask Typecraft for advice.

The score that works best and places the least amount of strain on the paper crease is one in which the ridge bends inward, running with the grain. Simply put, a scored sheet when laid flat should contain a bump, not a dip.

FOLDING

Folds come in two types: parallel and right angle. The folds you make before you put a standard- size sheet of paper into a business envelope are good examples of folding; two creases in the same direction, ideally along the paper grain.

A right angle fold is two or more folds, with each fold at right angles from the previous one.

To make clean folds, many jobs require small variations in panel size. While they may look similar, individual panels are sized at slight differences to accommodate for paper thickness.

It’s worth remembering that the more folds you have, the lighter the weight of paper required. That’s because heavier stock may build up too much thickness to roll into itself a number of times. Or may requires wider scoring.

FOREST STEWARDSHIP COUNCIL® (FSC®)

Typecraft became a Forest Stewardship Council (FSC) certified Chain-of-Custody printer in July, 2006 (SCS-COC-000864).

LOOK FOR FSC CERTIFIED PRODUCTS.

The FSC is an international non-profit made up of social, environmental, and business concerns, and grew out of the 1992 Rio Earth Summit. Groups such as the Rainforest Alliance and Forest Ethics support FSC standards, which require that paper products come from healthy managed forests. In addition, the FSC tightly controls standards to reject wood products that originate in forests where traditional or civil rights are violated.

The origins of every sheet of FSC-certified paper are documented back to the harvesting of the tree, and the documentation includes all processing and handling right up to when the printed piece leaves our premises. As a certified printer, we have the right to reproduce the environmentally-friendly FSC logo on your printed materials. The use of the FSC logo demonstrates your commitment to healthy environmental practices.

There is a broad selection of FSC certified paper stock available for any print project. The stocks come coated or uncoated, in cover and text weights. There are recycled sheets made with 100% post-consumer waste; virgin-fiber stocks, and even paper manufactured using wind energy.

Please call Typecraft to find out how to produce your next project on an FSC-certified paper stock, and join us in a sustainable future.

FSC available by request.

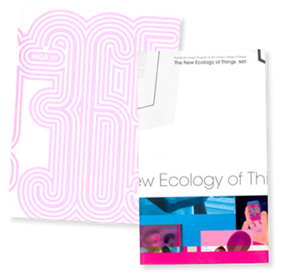

AIGA

Typecraft is very pleased to announce that a book we printed made it into the AIGA Year in Design publication. The New Ecology of Things book that we printed with Anne Burdick from the Media Design Program at Art Center College of Design has been selected as one of the books in the 50 Books / 50 Covers competition.

This description comes from the AIGA Design Archives site:

The New Ecology of Things (NET) is a research initiative that explores emerging forms of interactive communication brought about by pervasive networked technologies. The project began as a studio class run by the Art Center’s graduate Media Design program, co-taught by Bruce Sterling, Phil van Allen and Nik Hafermaas and sponsored by Sun Microsystems Labs. It has since evolved into a transmedia publication, an ongoing series of projects, technological inventions and new issues for design pedagogy.

The New Ecology of Things transmedia publication embraces and embodies NET connectivity by speaking across multiple media forms. The NET publication includes essays, a glossary, forums, interactive works and videos. Writing from Bruce Sterling, Brenda Laurel, Phil van Allen, Anne Burdick, Holly Willis and Nik Hafermaas joins NET projects designed by Art Center students, friends and faculty.

Each of the four media components —book, dust jacket/poster, website (newecologyofthings.net) and mobile content—relates to the others: place the book on the poster to see additional imagery; point your mobile camera-phone at barcodes on the poster and watch videos; browse URLs in the book and move to a dialog online.

We are grateful to Anne and all of her team for the opportunity to work with them on their projects.

David Mayes assertion of flexible page count; can enhance aethetics for specialty pieces. Disadvantages: Prevents pages from opening flat.

Wire-O and Spiral: A method in which pages and cover are held together by a metal coil. Though more expensive than wire-stitching, mechanical bindings allow their contents to open wide and lie perfectly flat. Advantages: Lays flat; pages can be removed without detection; adaptable to different paper types; offers single-sheet insertion for flexible page count; bindings come in a wide variety of colors. Disadvantages: Expense; can detract from project aesthetics.

Perfect Binding: Most annual reports and bigger catalogs employ this attractive method, in which pages are assembled in groups, or signatures, and bound together with flexible adhesive, then covered. Advantages: Accommodates greater number of pages and higher page weights than saddle-stitch; accommodates multiple sheet weights and sizes; allows intermix of stocks, provides clean, finished edge. Disadvantages: After pages are collected into signatures, binding edge is ground off to improve adhesion. Does not lay flat; crossover images and type may be lost in the gutter.

Case or Edition: The conventional method used in most hardcover books. Sheets are folded into 16- or 32-page signatures, pasted with end leaves and sewn together. This process culminates in a hardcover, which ensures durability for years to come. Advantages: Provides perfect crossover of images page to page; archival quality. Disadvantages: Most expensive binding method.

Scoring: In general, you will want to channel score if your stock is 100-lb. text or heavier, or if the job’s height/width ratio is greater than 3:1. If your stock is 80-lb. text and folds against the grain, ask Typecraft for advice.

The score that works best and places the least amount of strain on the paper crease is one in which the ridge bends inward, running with the grain. Simply put, a scored sheet when laid flat should contain a bump, not a dip.

Folding: Folds come in two types: parallel and right angle. The folds you make before you put a standard- size sheet of paper into a business envelope are good examples of folding; two creases in the same direction, ideally along the paper grain.

A right angle fold is two or more folds, with each fold at right angles from the previous one.

To make clean folds, many jobs require small variations in panel size. While they may look similar, individual panels are sized at slight differences to accommodate for paper thickness.

It’s worth remembering that the more folds you have, the lighter the weight of paper required. That’s because heavier stock may build up too much thickness to roll into itself a number of times. Or may requires wider scoring.

2040 EAST WALNUT STREET, PASADENA, CA 91107 - 626.795.8093 || 520 LAGUNA STREET, SANTA BARBARA, CA 93101 - 805.845.2860 || CONTACT